If you’re seeking to integrate dynamism into your aesthetic space, consider pieces fabricated from corrosion-resistant alloys like stainless steel 316 or naval brass (C46400). These materials offer superior longevity and weathering capabilities, crucial for outdoor installations, especially in coastal environments. Proper anchoring is paramount: calculate wind load factors for your specific geographic location using the ASCE 7-16 standard to determine the necessary foundation depth and fastener strength.

Exploring the creations of Theo Jansen, known for his Strandbeests, provides insight into complex linkage systems. His use of PVC pipe and recycled materials demonstrates innovative approaches to structural engineering. Consider incorporating counterweights strategically to optimize balance and reduce stress on moving parts. Examining patents for existing mechanisms, searchable on the USPTO website, can offer inspiration and prevent unintended infringement.

For enhanced visual impact, experiment with surface treatments like patination using chemical solutions containing copper sulfate or ferric nitrate. These processes can accelerate the aging process, creating unique and compelling surface textures. Remember to seal the surface afterward with a UV-resistant lacquer to preserve the finish and prevent further oxidation. Accurate fabrication tolerances, often within +/- 0.005 inches, are critical for smooth operation; precision laser cutting or waterjet cutting are recommended for intricate components.

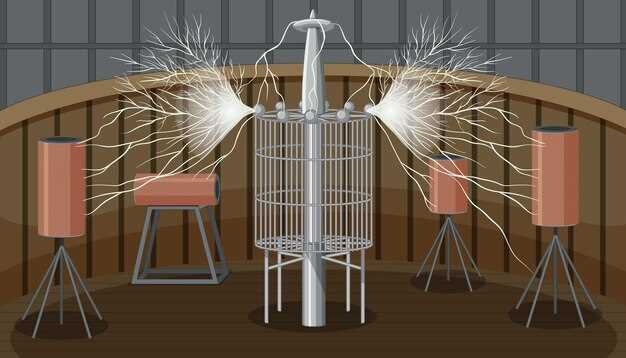

What Makes a Configuration “Ablaze”?

A creation qualifies as “ablaze” due to its dependence on physical forces for configuration alterations. Wind, gravity, or mechanics provide the impetus for its display. The central factor is an observable, continuous shift within the piece itself.

Consider the work’s components. If a configuration contains elements designed for sustained, self-generated actions – for example, a mechanism powered by a spring – it aligns with the classification. Conversely, a fixed formation, however visually intriguing, does not qualify. The key is continual adaptation.

Assess the extent of the dynamic traits. A mobile with several rotating sections, propelled by airflow, exemplifies this category. A figurine merely posed to suggest a stride, despite implying activity, does not constitute an animated object, unless it incorporates a physical component that actually alters its pose.

Examine the source of the activation. The device should actively incorporate a method for its movement. An item moved manually by a viewer can be categorized as interactive, yet it doesn’t possess the inherent attributes of self-actuation. The alteration must stem from an integral design element.

Materials Best Suited for Moving Metal Creations?

For lightweight, responsive pieces, aluminum alloys like 6061 offer excellent strength-to-weight ratios. This allows for minimal energy input to initiate and maintain movement. Consider its susceptibility to surface scratches, requiring protective coatings.

Stainless steel grades 304 and 316 provide exceptional corrosion resistance for outdoor installations. Grade 316, with added molybdenum, performs particularly well in saline environments. The higher density requires stronger drive mechanisms or counterbalance techniques for fluidity.

Brass, particularly alloys with higher copper content, provides visual warmth and ages beautifully. Its machinability facilitates intricate detailing. Be mindful of its propensity to tarnish, which can be mitigated with regular polishing or protective lacquers.

Specialized Alloys for Specific Needs

Spring steel, typically high-carbon steel alloys, offers superior elasticity for elements requiring repetitive flexing or energy storage. Careful heat treatment is vital to achieve the desired spring rate and prevent premature failure. Its lower corrosion resistance makes protective coatings a must.

Titanium grades offer unmatched strength-to-weight performance and corrosion resistance, albeit at a higher cost. This makes them ideal for large-scale installations where minimizing mass is crucial, or for exposed environments where longevity is paramount. The welding of titanium demands specialized techniques and equipment.

Factors influencing material Selection

The choice should integrate the intended environment, operational parameters (speed, range of motion), and desired aesthetic. Material thickness and joinery methods strongly affect the mechanical behavior and longevity of the piece. Prototypes and testing are advised, particularly for complex mechanical systems.

Powering Your Crafted Automatons: Motors vs. Wind?

For consistent rotational artworks, use geared DC motors. Select motor torque based on the animated piece’s weight & desired speed. A 12V DC motor with 50 oz-in of torque adequately powers a 5lb mobile rotating at 5 RPM. Consider PWM speed controllers for adjustable tempo. For smaller, lightweight automata, stepper motors allow precise incremental advancement. Bi-directional movement is achievable, widening compositional capabilities.

Wind Power Advantages

Wind-powered creations demand careful balancing. Employ lightweight materials like aluminum or composite for blades. Blade pitch influences torque and operating speed. Darrieus vertical-axis wind contraptions are omnidirectional, obviating a yaw mechanism. Consider incorporating a brake system to prevent damage during high-wind conditions. Include a weather vane to indicate wind direction.

Motor Power Advantages

Direct current motors offer regulated, on-demand actuation. Integrate microcontrollers such as Arduino to pre-program elaborate sequences of movement. Utilize position sensors (e.g., encoders) to manage precise placement. AC motors are more suitable for heavier constructions, but require AC power availability.

Maintaining the Propulsion: Inhibiting Oxidation & Attrition

Apply a thin coat of Renaissance Wax or a similar microcrystalline wax polish every 6-12 months to protect the kinetic structures’ surfaces. This barrier shields the reactive surfaces from moisture and airborne pollutants, primary catalysts for oxidation. For structures placed outdoors, consider increasing the application frequency to quarterly.

Lubricate moving parts, such as bearings and pivots, with a PTFE-based dry lubricant. Unlike oil-based lubricants, PTFE doesn’t attract dust and debris, which accelerates abrasion. Re-lubricate every 3 months or as needed, depending on the complexity’s exposure to the elements.

Periodically inspect welds and connections for signs of fatigue or cracking, especially in areas subjected to high stress. Repair any identified weaknesses via TIG welding using appropriate filler rods that match the composition of the primary material. Document these repairs in a maintenance log.

If the construction utilizes dissimilar compounds, mitigate galvanic corrosion by applying a barrier coating, such as zinc chromate primer, between the components. Regularly check the coating’s integrity and reapply as needed.

For painted or powder-coated works, use pH-neutral cleaning solutions to remove dirt and grime. Abrasive cleaners will damage the finish, exposing the surface beneath to the elements. After cleaning, reapply wax or sealant to further protect the covering.

When the aesthetic display incorporates gears, shafts, or other rotating elements, ensure proper alignment. Misalignment induces uneven wear. Utilize shims and precision measurements to correct any deviations.

Install sacrificial anodes, specifically zinc or magnesium, for installations near saltwater environments. These anodes corrode preferentially, protecting the artwork from deterioration.

Where to See Stunning Dynamic Metalwork Displays

The Exploratorium in San Francisco features several interactive exhibits with moving constructions, including pieces by Arthur Ganson. See his whimsical mechanisms engage with scientific principles.

The Tinguely Museum in Basel, Switzerland, is dedicated to the creations of Jean Tinguely. The museum’s collection showcases his complex, often humorous, automated contraptions. Expect elaborate, noisy constructions engaging in unexpected activities.

The MIT Museum in Cambridge, Massachusetts, houses a collection of rotating works created by Arthur Ganson. These elaborate, often humorous devices, demonstrate engineering ingenuity.

For large-scale, outdoor moving works, visit the Frederik Meijer Gardens & Sculpture Park in Grand Rapids, Michigan. Their collection includes several sizable pieces that interact with wind and environment.

Local galleries and specialized craft fairs frequently showcase pieces by independent creators. Search for nearby events and exhibits focusing on innovative constructions or automate design.

The Museum of Modern Moving Items (MoMA) in New York City occasionally exhibits dynamic constructions as part of its contemporary design collection. Check their online catalogue for current and past displays.

Consider attending events like the Maker Faire, where hobbyists and inventors display their ingenious devices and mechanisms, including unique, self-operating forms. Discover novel creations and engineering feats.

View YouTube channels dedicated to the work of independent artists. Many creators document their process and showcase completed projects, giving you a virtual experience of their creations.

Question-answer:

What makes a sculpture “kinetic”? I see metal sculptures all the time, but how is a kinetic piece different?

A kinetic sculpture is distinct because it incorporates movement as a fundamental element of its design. It’s not just a static object; it’s designed to move, often through air currents, motors, or other mechanical means. The movement becomes part of the artwork’s expression. Think of it as bringing a drawing to life, but in 3D, with metal, and with purposeful motion.

What kinds of metal are commonly used in building these moving sculptures? Are there specific metals that work better than others?

Various metals are employed depending on the desired effect, the size of the sculpture, and the artist’s preference. Stainless steel is popular because of its resistance to corrosion and its strength, allowing for thin, strong elements. Aluminum is lightweight, making it suitable for pieces designed to move easily in the wind. Copper and brass can also be used, often for their aesthetic appeal and the patina they develop. The choice depends on the balance between durability, weight, and the visual impact sought.

I’m curious about how these sculptures are powered. Are they all wind-powered, or are there other ways to make them move?

While wind power is a frequent method for activating kinetic sculptures, it is not the only way. Many artists utilize electric motors, sometimes concealed within the sculpture’s base, to create controlled, predictable movements. Water can also be employed, either through a water wheel mechanism or via strategically placed nozzles that cause elements to rotate or oscillate. Some artists also use manual cranks, allowing viewers to interact with the sculpture and set it in motion themselves. There is also the occasional use of magnets.

Are there any famous metal kinetic sculptors whose work I should examine to learn more about this art form?

Absolutely! Alexander Calder is recognized as a pioneer of the mobile, a type of kinetic sculpture. Jean Tinguely is another notable name, known for his complex, self-destructing machines. More contemporary artists include Anthony Howe, whose large-scale wind-powered sculptures are mesmerizing, and Theo Jansen, who creates “strandbeests” – complex, wind-powered walking sculptures. Researching their individual styles and approaches will provide insight into the diversity possible within metal kinetic sculpture.

The idea of a sculpture that moves is very appealing. Are there any factors to consider when purchasing one for my yard in terms of maintenance or placement? I’m worried about damage from weather.

Yes, several factors merit consideration. The location should be chosen to accommodate the sculpture’s movement. Consider wind direction and the space the moving parts will occupy. Maintenance depends on the materials. Stainless steel requires less attention, while other metals might benefit from occasional cleaning to prevent corrosion. Also, look into any guarantees or recommended maintenance procedures from the artist or seller. Secure mounting is also extremely important to prevent toppling, mainly in areas prone to strong winds. Check if the seller recommends regular checking of the mountings.