Seeking to acquire an impressive iron steed? Prioritize pieces fabricated from corten steel; its inherent rust-resistant qualities minimize long-term maintenance. Examine weld quality with magnification; consistent, even beads signal superior fabrication. Also, inquire about the internal bracing; a robust internal frame significantly increases the piece’s longevity, particularly in regions prone to high winds.

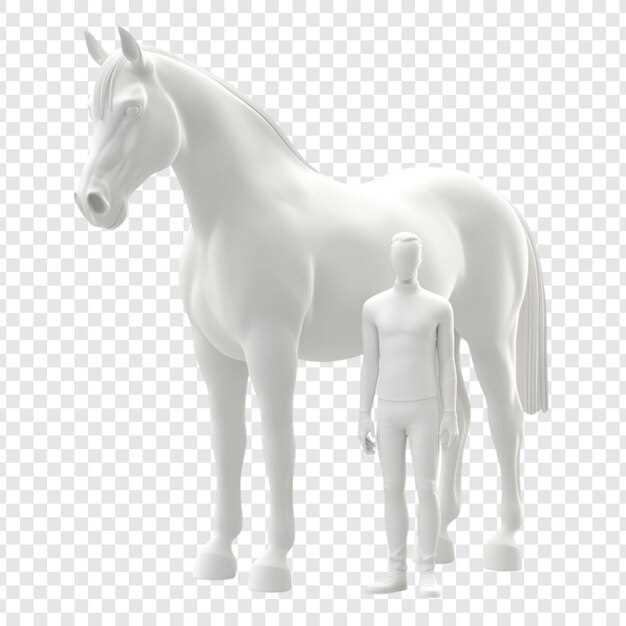

The enduring fascination with equine forms, realized through ferrous alloys, has yielded a diverse range of interpretations. This investigation focuses on the synthesis of structural integrity and aesthetic expression in these impressive creations. Ranging from representational effigies mirroring anatomical accuracy to abstract interpretations leveraging geometric forms, these crafted steeds represent a tangible dialogue between the artist’s vision and the material’s inherent properties.

This analysis explores specific case studies, analyzing the methods employed by contemporary artisans. We examine the lost-wax casting technique used by Deborah Butterfield to create skeletal equine figures from recycled scrap, contrasting it with the direct metal assembly approach of John Lopez, who utilizes found objects – agricultural implements, industrial components – to construct large-scale creatures brimming with kinetic potential. This comparison reveals distinct approaches to material manipulation and narrative conveyance.

Choosing the Right Alloy for Equine Statues

For durable, outdoor equestrian figures, opt for silicon bronze (C65500). It exhibits superior corrosion resistance in diverse climates, retaining its aesthetic appeal for decades. Its weldability also simplifies complex constructions.

Stainless steel (316L grade) provides a modern aesthetic and excellent corrosion protection, especially near coastal environments. Its inherent strength allows for creating larger, more ambitious depictions of steeds.

For smaller, indoor equine figurines, consider brass (C26000). It offers a warm tone and polishes to a high sheen. Its softer nature allows for finer detailing and intricate textural work.

Weathering steel (ASTM A588) offers a distinctive, rustic look. The controlled oxidation forms a protective layer that minimizes further corrosion. It is suitable for large scale outdoor renderings, providing a unique visual appeal with minimal maintenance.

Aluminum (5052 alloy) presents a lightweight alternative, simplifying installation and transportation. Its excellent formability enables complex, flowing designs. Powder coating enhances its protection against environmental influences, allowing for a range of color options.

Designing a Dynamic Equine Effigy: Key Directives

Prioritize capturing the animal’s gestural essence early. Sketches focusing on weight distribution during movement provide a superior foundation compared to static anatomical studies.

Balance & Support

Evaluate the center of gravity rigorously during the conception stage. Computational fluid dynamics (CFD) simulations, typically used in engineering, can predict stress points and inform internal support structures for cantilevered sections of the figure.

Experiment with alloys offering high tensile strength-to-weight ratios, such as titanium or specialized steel grades. These allow for larger, more expressive forms with minimal internal bracing, preserving visual flow.

Material Selection & Manipulation

Consider patinas not simply as surface treatment, but as integral components of the kinetic illusion. A gradient finish mirroring light’s interaction with a galloping steed enhances perceived velocity.

Exploit perforation techniques to minimize wind resistance. Intricate cutouts, inspired by aerodynamic principles, can lessen sway in outdoor displays without sacrificing structural integrity.

Employ parametric modeling software to generate complex surface geometries that mimic muscle fiber arrangement. This technique adds both anatomical accuracy and visual dynamism to the fabricated creation.

Step-by-Step: Welding a Small-Scale Steel Equine Figure

Secure a stable welding surface before starting. 16-gauge mild steel is suitable for detailed, miniature equestrian effigies. Begin with the skeletal structure, tack welding the legs to the torso form. Use a Lincoln Electric Power MIG 210MP for versatile amperage control on thin stock, setting the voltage around 16V and wire feed speed to 200 IPM.

Constructing the Equine Form

Cut the primary components (legs, body, neck, head) using a plasma cutter for precise edges. A Hypertherm Powermax30 XP offers portability and fine-cut capability. Tacking is crucial; small welds prevent warping. Focus on joint integrity, aligning pieces with clamps before applying heat. A set of adjustable magnetic welding clamps can simplify holding awkward angles.

Detailing and Finishing

Add musculature by layering progressively smaller steel pieces. Use a rotary tool with a grinding disc to smooth welds and blend the add-ons into the framework. Consider using different wire diameters depending on the degree of filling needed; a 0.023″ wire is better for intricate surface blending than a 0.030″ wire. Apply a rust-preventative coating, such as Eastwood Anti-Rust, after completion to protect the piece. Buff the finish with a wire wheel for a polished look.

Protecting Your Equestrian Effigy from the Elements

Apply a sealant specifically formulated for the effigy’s composition annually. For bronze likenesses, use Renaissance Wax. For steel figures, consider a clear coat lacquer containing UV inhibitors. This shields against fading and corrosion.

Clean the artwork regularly with a soft cloth and pH-neutral soap. Avoid abrasive cleaners, which can scratch the surface. For stubborn grime, use a diluted solution of baking soda and water, gently rubbing with a non-abrasive sponge.

Location Matters

Position the artistic rendering strategically. Avoid direct contact with soil, which can wick moisture and accelerate deterioration. If outdoors, elevate it on a plinth made from weather-resistant material like granite or composite lumber.

Winter Precautions

In regions with freezing temperatures, ice expansion can damage the internal structure of hollow forms. Consider covering the figure with a breathable tarp or storing it indoors during the winter months.

Inspect the equine facsimile routinely for cracks, rust, or other signs of damage. Address minor issues immediately to prevent further deterioration. Consult a professional conservator for significant repairs or restoration.

Question-answer:

What are some of the most popular metals used for creating these horse sculptures, and what properties make them suitable for the task?

Commonly used metals include steel, bronze, aluminum, and copper. Steel provides strength and durability, enabling larger and more robust sculptures. Bronze is valued for its rich color and ability to capture fine details, plus it’s resistant to corrosion. Aluminum is lightweight and weather-resistant, suitable for outdoor installations. Copper offers a unique reddish hue and develops a beautiful patina over time, which many artists appreciate.

Beyond aesthetics, what are some practical aspects an artist must think about when designing a large-scale metal horse sculpture, especially one intended for public display?

Several practical concerns arise with large-scale pieces. The artist must consider structural integrity, ensuring the sculpture can withstand environmental factors like wind, rain, and snow. Weight distribution is vital for stability. Transportation and installation require careful planning, often involving specialized equipment. Also, selecting materials that resist vandalism and require minimal maintenance is beneficial for sculptures in public areas.

I’m interested in commissioning a metal horse sculpture. What’s a general idea of the process, from the initial consultation to the final installation?

Usually, the process begins with an initial consultation to discuss your vision, including size, style, material, and budget. The artist will then develop sketches or 3D models for your approval. Once the design is finalized, fabrication starts. This might involve welding, forging, casting, or a combination of techniques. Throughout the fabrication, you’ll receive progress updates. Finally, the sculpture is transported and installed at the desired location. Expect the entire process to take several weeks or even months, depending on the complexity.

How do artists protect their metal horse sculptures from rust and corrosion, particularly if the sculpture will be located outdoors in a humid climate?

Several methods exist to protect metal sculptures from corrosion. Applying protective coatings, such as sealants, paints, or powder coatings, creates a barrier against moisture. Galvanization, where a layer of zinc is applied to the steel, is also effective. Using corrosion-resistant metals like stainless steel or bronze minimizes the problem from the outset. Regular cleaning and maintenance are also important to remove dirt and debris that can trap moisture.

Are there specific sculptors who are particularly known for their metal horse sculptures? If so, could you mention a few and perhaps a distinctive feature of their style?

Yes, many sculptors have made a name for themselves with their equine creations. Deborah Butterfield, for example, is famous for her sculptures of horses made from found metal and scrap, often evoking a sense of fragility and resilience. Nic Fiddian-Green is known for monumental horse heads that capture the animal’s power and grace. These are just two examples, and each artist brings a singular approach to the subject.